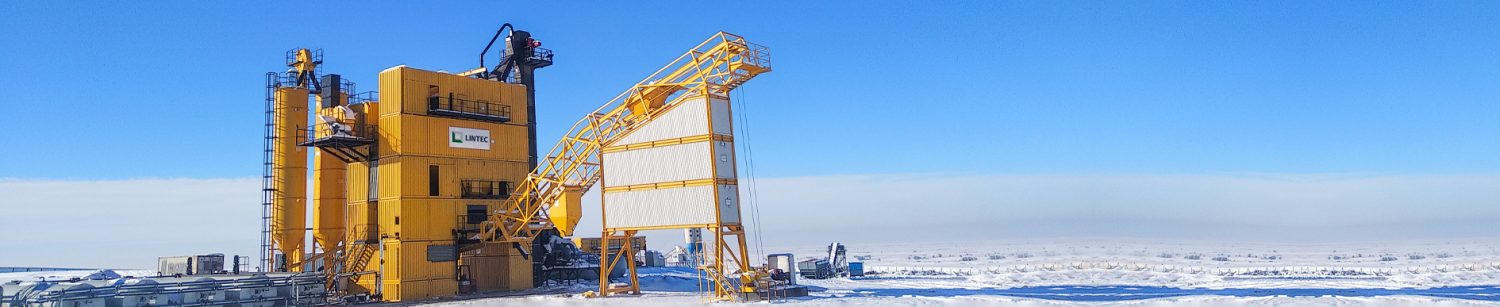

The Linnhoff TSD MobileMix Asphalt Batch Mix Plant series features mobility with ease of installation, enabling the bitumen mixing plants to be frequently relocated to different job sites. These hot mix asphalt plants are suitable for short-term projects or projects in remote locations. It is designed to maximise the plug-and-play convenience whilst minimising the time spent on mobilisation and demobilisation, with no heavy cranes and heavy-concrete foundations required for its setup.

| Model | TSD1000 | TSD1500 | TSD2000 |

| Capacity | 40-60 | 100-120 | 120-160 |

| Batch Size | 1150 kg | 1500 kg | 2000 kg |

*Capacity as per standard plant performance based on 3% moisture content. Specifications are subject to technical modifications.